Many people in Ontario, Canada, know how to use propane in their daily lives to heat their water, warm their houses, power their appliances, cook their food and much more - but do you know how propane is made?

Propane was first identified as a compound in gasoline in 1911, with scientists recognizing that propane gas could easily be converted to liquefied petroleum gas (LPG) at the right temperature and pressure.

Over the next 10 years entrepreneurs worked together to find out how they could both produce propane and start marketing it as a viable source of fuel.

Today, propane is hugely popular for a wide variety of residential and commercial applications. This is largely down to how safe it is as a fuel source, the fact it’s environmentally-friendly and its cost-effective nature.

How is propane produced?

Propane processing has changed in a large number of ways since its early years, and there are two main ways that propane is produced today - refining and natural gas production.

1 - Propane from natural gas production

Propane, along with butane, is extracted from liquid components during natural gas processing to prevent condensation in natural gas pipelines. Since propane is 270 times denser as a liquid than as a gas, the extracted propane is stored and transported as a liquid.

The next step is to add an odorant into the propane because it is naturally colorless and odorless. This ensures that in the rare event of a propane leak, you will easily be able to work out where it’s coming from.

2 - Propane from crude oil refining

At various stages during the oil-refining process, liquefied petroleum gases are produced. During the fractional distillation under pressure, or stabilization stage of crude oil refining, heavier hydrocarbons sink to the bottom, whereas lighter hydrocarbons such as propane are easily removed from the top layer of the mix.

While the actual percentage of propane extracted from the crude oil depends on the process and the type of refinery, butane and propane generally constitute around 1-4% of processed crude oil.

Liquefying propane

Liquefying propane is critical for its storage and transportation. Despite being created as a gas, propane is stored and transported as a pressurized liquid at 177 PSI. You will more than likely notice this when you carry a propane tank at your home or business, since you can feel liquid moving inside. When it is released into the air, propane changes to gas.

The liquefying stage is critical for the successful production of propane. If some of the impurities and other hydrocarbons, such as ethane, propene or pentene, are not sufficiently removed, propane will not liquefy properly.

Not only that, but liquefaction must occur at the correct temperature and pressure and must follow the standardized specifications established by the liquefied gas industry. This liquefied form ensures propane is far safer than other energy sources for a variety of applications.

Why does the propane production method matter?

Propane is produced and transported in a different way to other fuels, and, as a result, the propane market is somewhat unique. There are two main factors for this:

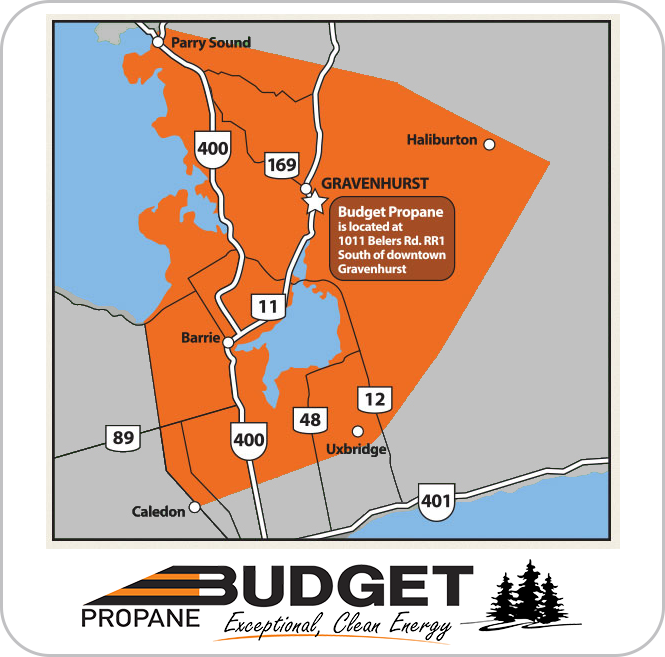

Domestic production: Canada is the seventh largest producer of propane and nearly 100% of Propane used in Canada is also made in Canada, with the rest being exported, mostly to the US. Propane is produced in every province except Manitoba, Nova Scotia and PEI, with 80% coming from Alberta, British Columbia, and Saskatchewan.

Propane is a byproduct: Propane is never created for its own sake, but it's a by-product of other processes. As a result, the availability of propane depends on production of natural gas and crude oil. Propane is abundant in Canada right now. However, since propane is a byproduct of producing other fuels, its availability is also tied to production of those other fuels.

Are you looking for more information about propane, and want to speak to an expert propane supplier based in Ontario? Contact the Budget Propane Ontario team of experts today, we would be more than happy to help.

.png?width=250&height=110&name=Copy%20of%20Untitled%20(3).png)